The Robot Industrialization Race: China’s Lead and the Challenges for the US and Underdeveloped Countries

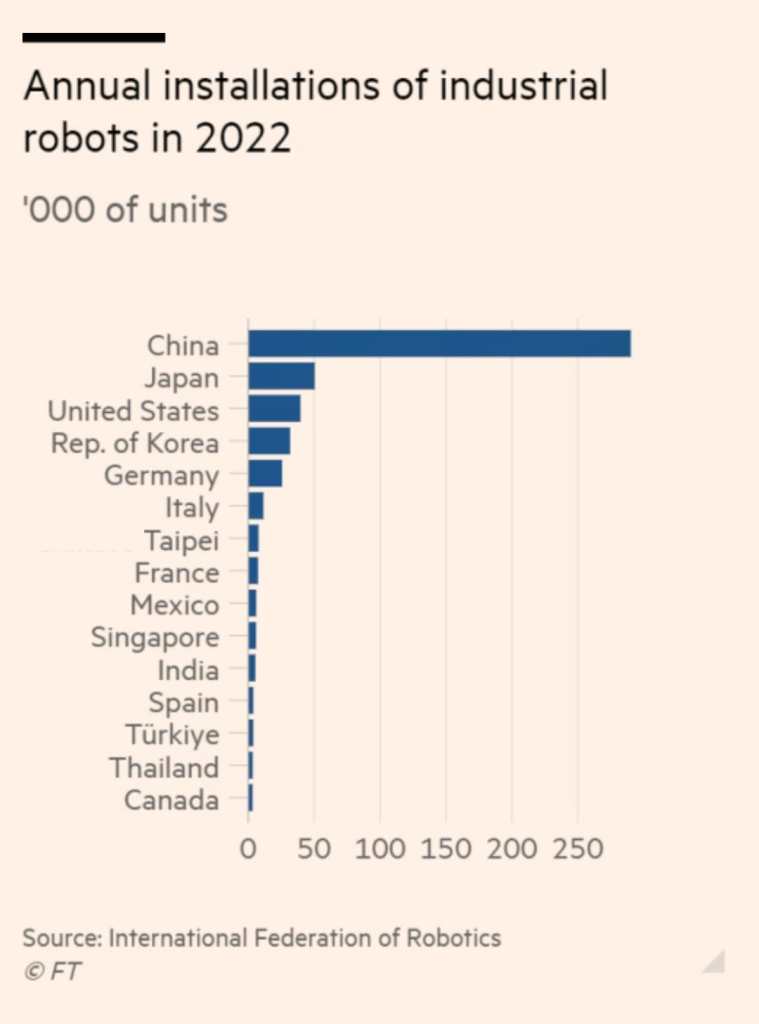

According to an analysis by Zhao DaShuai on Twitter, China appears to be far ahead in the robot industrialization race, posing significant challenges for the United States and underdeveloped countries like India to catch up.

However, it is important to approach this analysis with skepticism, as Zhao DaShuai self-identifies as part of the “People’s Armed Police Propaganda Bureau On Twitter” and states, “All forms of media is propaganda, we’re just more honest about it.”

Challenges for the US and Underdeveloped Countries

Manufacturing high-end industrial robots is a complex task, with only China, Germany, and Japan possessing the entire supply chain. For example, China’s Chietom is one of the few companies worldwide that produces high-end RV reducers, which account for approximately 36% of a robot’s cost.

Moreover, having a complete supply chain is crucial for a country to have a comparative advantage in manufacturing.

As Zhao DaShuai explains, “For underdeveloped countries like india calibrating high precision CNC machines is an impossible task without foreign suppliers. Because high precision equipment like these interferometers have reached sub-nanometer class.”

China’s Advantage

China’s advantage lies in its complete supply chain and nation-wide manufacturing standard. With Industry 4.0, this standard is manifested through interconnected digital platforms.

“China has 150+ digitized platforms connecting 80+ million robots in manufacturing, this digital network is the industry 4.0,” states Zhao DaShuai.

Counterarguments and Discussions

Some argue that China’s robotics and high-end CNC machine industry faced significant competition from German and Japanese companies from the 1980s to early 2000s, and that Chinese companies have only recently regained market share through indigenous development.

Others point out that industrial robots, specifically robotic arms, are not the most common or directly useful manufacturing machinery, with CNCs, laser cutters, breaks, and injection molds being more widely used.

The need for increased energy production in the US is also highlighted, with one commenter stating, “You also need to look at power generation. China produces twice as much electricity as the US.

As a result the US would need to massively increase energy production to reach China’s level of automation.”

However, some believe that with the right incentives, the US could catch up within a matter of years.

“If there are incentives to innovate, there will be innovation, especially in America. America would catch up within a matter of years if industrialization and automation becomes profitable,” argues one commenter.

Current State of Robot Industrialization

The current state of robot installation by country shows China’s leading position in the field. However, as one commenter pointed out, “China’s industrialisation was driven by Western investments and technology. What was done in China can also be done elsewhere.”

Is China Leading the Global Robot Industrialization Race?

While China appears to be leading the robot industrialization race, the analysis by Zhao DaShuai should be approached with caution due to the author’s self-identified propaganda role.

The challenges for the US and underdeveloped countries in catching up are significant, including the difficulty in manufacturing high-end industrial robots, the importance of a complete supply chain, and the need for increased energy production.

However, with the right incentives and investments, it may be possible for other countries to close the gap, as China’s industrialization was driven by Western investments and technology. The future of robot industrialization and global competition remains uncertain, and it will be crucial to monitor developments in this field closely.

What do you think? Is China leading the race? Does the United States need to accelerate its robotic industrialization?